Dej-raws li zinc-nplua nuj primer rau steel qauv

Khoom ua haujlwm

Zoo tiv thaiv corrosion muaj peev xwm ua tau raws li kev tiv thaiv ntawm tag nrho cov txheej;

Siv dej los ua qhov nruab nrab dispersion, tsis muaj tshuaj lom thiab muaj teeb meem tshwm sim thaum lub sij hawm tsim kho thiab txheej txheem txheej txheej zaj duab xis, uas ua tau raws li cov kev cai ntawm kev tiv thaiv ib puag ncig;ob-tivthaiv curing, zoo hardness, zoo adhesion, thiab tshuaj tsis kam;

Kev sib raug zoo yog qhov zoo, cov yeeb yaj kiab txheej yog ruaj khov rau cov hlau substrate, thiab cov adhesion ntawm cov txheej txheej sab saud tuaj yeem txhim kho.

Kev siv ntau yam

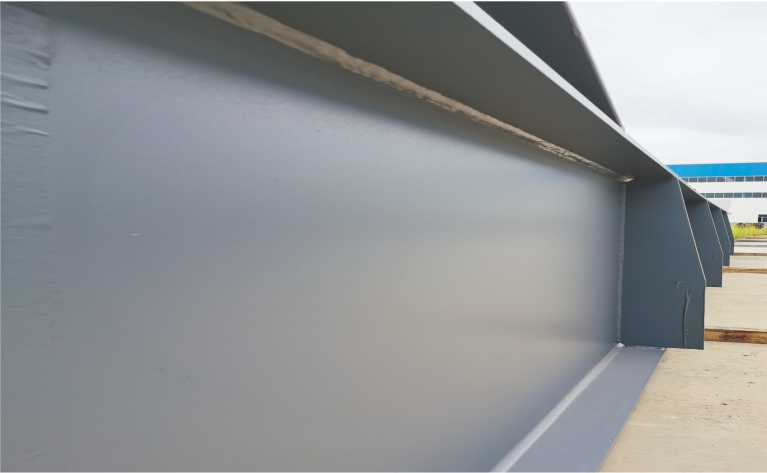

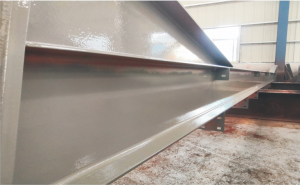

Nws yog qhov tsim nyog rau kev tiv thaiv xeb thiab tiv thaiv corrosion ntawm cov hlau hnyav ntawm ntau yam steel hlau loj, nkoj, khoom siv kho tshuab, txuas hniav, thiab lwm yam.

Kev kho saum npoo

Tshem tawm cov roj, roj, thiab lwm yam nrog tus neeg saib xyuas tsim nyog.Sandblasted rau qib Sa2.5 lossis SSPC-SP10 qib, qhov roughness saum npoo yog sib npaug rau Rugotest tus qauv N0.3.Kev tsim kho tsis pub dhau 6 teev tom qab sandblasting yog qhov kev daws teeb meem zoo tshaj plaws.

Kev piav qhia kev tsim kho

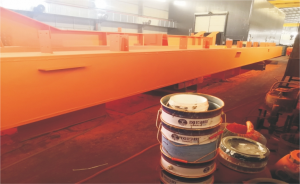

Nws tuaj yeem siv los ntawm cov menyuam, txhuam thiab tshuaj tsuag.Kev kub siab airless tshuaj tsuag yog pom zoo kom tau ib tug zoo li qub thiab zoo txheej zaj duab xis.

Ua ntej kev tsim kho, AB tivthaiv cov khoom ua kua yuav tsum tau nplawm tusyees nrog lub tshuab hluav taws xob, thiab tom qab ntawd cov khoom siv AB yuav tsum sib tov sib npaug.Ua ntej kev tsim kho, nws raug nquahu kom kaw qhov nkag nkag nrog 80-mesh lim.Yog hais tias lub viscosity yog tuab heev, nws tuaj yeem diluted nrog dej rau kev tsim kho viscosity.Txhawm rau kom ntseeg tau qhov zoo ntawm cov xim pleev xim, peb pom zoo tias qhov nyiaj dilution yog 0% -10% ntawm cov xim qub qub.Tus txheeb ze av noo yog tsawg dua 85%, thiab kev tsim kho qhov kub thiab txias yog siab dua 5 ° C thiab siab dua qhov dej dew point kub los ntawm 3 ° C.Los nag, daus thiab huab cua tsis tuaj yeem siv sab nraum zoov.Yog tias kev tsim kho twb tau ua tiav lawm, cov xim pleev xim tuaj yeem tiv thaiv los ntawm kev npog nws nrog tarpaulin.

Pom zoo pob

Primer FL-128D / 133D dej-raws li inorganic epoxy zinc-nplua nuj 1-2 zaug

Intermediate xim FL-123Z dej-raws li epoxy micaceous hlau intermediate xim 1 zaug

Topcoat FL-139M / 168M dej-raws li polyurethane / fluorocarbon topcoat 2 zaug, txuam thickness tsis tsawg tshaj 250μm

Tus txheej txheem tswj hwm

HG/T5176-2017

Txhawb kev tsim kho cov txheej txheem

| Gloss | Matte |

| xim | grey |

| Volume cov ntsiab lus | 50% ± 2 |

| Cov ntsiab lus zinc | 10% -80% |

| Theoretical txheej tus nqi | 10m² / L (qhuav zaj duab xis 50 microns) |

| Lub ntiajteb txawj nqus tshwj xeeb | 1.6-2.8kg / L |

| Deg qhuav (50% humidity) | 15 ℃ ≤ 1h, 25 ℃ ≤ 0.5h, 35 ℃ ≤ 0.1h |

| Ua haujlwm nyuaj (50% av noo) | 15 ℃ ≤ 10h, 25 ℃ ≤ 5h, 35 ℃ ≤ 3h |

| Recoating lub sijhawm | yam tsawg kawg 24 h;siab tshaj unlimited (25 ℃) |

| Ua kom tiav | 7d (25 ℃) |

| Hardness | H |

| Adhesion | Qib 1 |

| Kev cuam tshuam tsis kam | 50kg.cm (inorganic zinc nplua nuj tsis tas yuav) |

| Mixed siv sijhawm | 6h (25 ℃) |