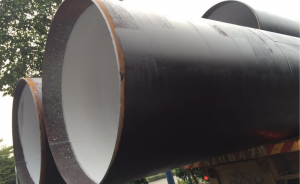

Heavy-duty anti-corrosion xim series rau sab hauv phab ntsa ntawm cov dej-raws li roj av cia tso tsheb hlau luam

Kev ua tau zoo sib xws

Zoo tiv thaiv corrosion muaj peev xwm ua tau raws li kev tiv thaiv ntawm tag nrho cov txheej;

Tsis muaj tshuaj lom thiab tsis zoo yog tsim nyob rau hauv qhov nruab nrab dispersion, kev tsim kho thiab txheej txheej txheej txheej txheej, uas ua tau raws li cov kev cai ntawm kev tiv thaiv ib puag ncig;dual muaj pes tsawg leeg, zoo hardness, zoo adhesion, tsis kam mus rau ntau yam roj, thiab zoo heev tshuaj tiv thaiv;

Kev sib txuam yog qhov zoo, cov yeeb yaj kiab txheej yog ruaj khov rau cov hlau substrate, uas tuaj yeem txhim kho qhov adhesion ntawm cov yeeb yaj kiab sab saud;kev tsim kho hauv lub tank tuaj yeem tsim nyog ua kom lub teeb pom kev zoo tsis muaj hluav taws kub thiab ua kom muaj kev tsim kho zoo.

Kev siv ntau yam

Cov khoom uas tsis yog-conductive yog tsim rau txheej tiv thaiv ntawm qhov chaw uas tsis tas yuav muaj hluav taws xob zoo li qub, xws li cov roj tank thiab cov ru tsev ntab.

Txheej kev tiv thaiv ntawm sab hauv phab ntsa ntawm cov kaus poom, thiab lwm yam. Cov khoom siv hluav taws xob yog tsim rau sab hauv phab ntsa ntawm cov roj tank tiav (diesel, kerosene, roj volatile, ntau yam roj av, thiab lwm yam) thiab lwm yam txheej txheej tiv thaiv nrog kev tiv thaiv zoo li qub.

Kev kho saum npoo

Txhua qhov chaw yuav tsum tau coated yuav tsum tsis muaj roj thiab plua plav thiab yuav tsum tau ceev kom huv si, qhuav thiab tsis muaj kab mob thiab txhua qhov chaw yuav tsum tau soj ntsuam thiab kho raws li ISO8504:1992.Nws yuav tsum tau mus txog qib Sa2.5, thiab cov primer yuav tsum tau siv li ntawm 6 teev tom qab sandblasting.

Kev piav qhia kev tsim kho

Kev kub siab airless txau yog pom zoo kom tau txais ib qho kev sib xws thiab cov yeeb yaj kiab zoo.

Sib tov tusyees raws li qhov proportions.Yog hais tias lub viscosity yog tuab heev, nws tuaj yeem diluted nrog dej rau kev tsim kho viscosity.Txhawm rau kom ntseeg tau qhov zoo ntawm cov xim pleev xim, peb pom zoo kom tus nqi dilution yog 0% -5% ntawm qhov hnyav xim thawj.Tus txheeb ze av noo yog tsawg dua 85%, thiab kev tsim kho qhov kub thiab txias yog siab dua 10 ° C thiab siab dua qhov dej dew point kub los ntawm 3 ° C.

Pom zoo pob

Non-conductive electrostatic supporting primer FL-2018D dej-raws li epoxy primer 3 zaug

Topcoat FL-2018M dej-raws li epoxy topcoat 4 zaug, qhov sib txuam thickness tsis tsawg dua 350μm

Static conductive txhawb primer FL-2019D dej-raws li epoxy electrostatic conductive primer 2 zaug

Topcoat FL-2019M dej-raws li epoxy electrostatic conductive topcoat 3 zaug, qhov sib txuam thickness tsis tsawg dua 250μm.

Tus txheej txheem tswj hwm

GB/T50393-2017

Txhawb kev tsim kho cov txheej txheem

| Lub sijhawm ziab (25 ℃) | nto qhuav ≤ 4h, nyuaj qhuav ≤ 24h |

| Recoating ncua sij hawm (25 ℃) | yam 4h,7d |

| Flexibility mm | 1 |

| Ua haujlwm rau 90-100 ℃ dej kub | 48h ib |

| Surface resistance (conductive xim) | 108-1011 ib |

| H2S, Cl-corrosion kuj (1%) | 7d tsis muaj qhov txawv txav |

| Acid kuj (immersed hauv 5% H2SO4 tov rau 30d) | tsis hloov |

| Roj tsis kam (immersed hauv 97 # roj av rau 30d) | tsis hloov |

| Cov ntsiab lus ruaj khov | 58-62% |

| Mixed siv sijhawm (25 ℃) | ≥ 4h |

| Adhesion (lub voj voog txoj kev) qib | 1 |

| Hardness (xws li hardness) | ≥ HB |

| Conductive hmoov electrode muaj peev xwm (v) | 0.1 |

| Impact resistance Kg.cm | ≥50 |

| Dej ntsev tsis kam (immersed hauv 5% NaCl tov rau 30d) | tsis hloov |

| Alkali tsis kam (immersed hauv 5% NaOH tov rau 30d) | tsis hloov |